You implement a process change and discover three weeks later that it created a new bottleneck that costs $50K monthly. Your team spent months planning, but you had no way to predict the ripple effects.

What if you could see the impact of a process change before investing time and money? What if you could experiment freely without disrupting your operations? iGrafx Process360 Live delivers exactly this capability through its discrete event process simulation engine.

The following article shows you how Process360 Live’s what-if scenario modeling optimizes processes without risk, forecasts outcomes with data-driven confidence, and removes uncertainty from transformation initiatives.

You’ll see real results from organizations already using this approach, plus get a straightforward action plan to start simulation now.

Why Changing a Process Feels Like a Gamble (And How to Fix It)

When a critical business process underperforms, whether it’s invoices getting stuck or service delays causing missed SLAs, operations leaders face a dilemma. You can either leave things as they are (and watch the pain continue),or try a change and hope it works. Too often, teams choose the latter with fingers crossed, which explains why 60-70% of process improvement initiatives fizzle out or fail to deliver results.

The core problem is uncertainty. Predicting how a process will behave after a change feels impossible. Will adding an approval step reduce risk or just slow things down more? If you hire two extra resources, will throughput improve enough to justify the cost? Without hard data, you’re betting your time and budget on educated guesses. It’s hard to see the outcomes.

This visibility gap stems from fundamental limitations in traditional approaches. Static flowcharts and spreadsheet models miss operational complexity, manual documentation captures how processes should work rather than how they actually work, and time studies provide snapshots instead of comprehensive behavior views.

Variables interact unexpectedly, bottlenecks shift without warning, resources conflict during peak periods, and pilot programs test changes in isolation while missing system-wide impacts. Meanwhile, what works perfectly at low volumes collapses when demand spikes, leaving teams scrambling to understand what went wrong.

Without process simulation, every process change becomes a live experiment with your operations as the test bed.

Process360 Live Eliminates the Process Uncertainty

As iGrafx CEO Alexandre Wentzo puts it, “Simulation is a crystal ball for your business, allowing organizations to understand the positive and negative consequences of making a process change without requiring an investment up front.”

Process360 Live creates a dynamic portion of the digital twin of your operations. This functions as a working replica that behaves like your actual processes, complete with variability, resource constraints, and real-world complexity.

You may use Process Mining to help you build a picture of how the process actually operates, including gathering and analyzing data that can help you build hypotheses to test in simulation, and gather some of the data needed to use simulation. The Mining platform starts by taking data from your existing systems to discover how work actually flows, then maps every activity, decision point, and handoff with statistical accuracy. This discovered process becomes the foundation for this part of your digital twin.

From there, you can build or update a valid process diagram, and enhance it into a simulation model. With your simulation model, you may test every proposed change in a risk-free digital environment before touching your actual operations. You see exactly how modifications ripple through your processes, measure precise impacts on cycle time, cost, and resource utilization, and identify which changes deliver results and which create new problems.

In other words, you get to see exactly what improvements will pay off (and what won’t) before you commit resources to improve (or design / re-design) the process.

By previewing changes in a risk-free digital environment, you solve the uncertainty problem. There’s no disruption to live operations, no costly pilot programs that might flop, and if an idea isn’t as effective as hoped, you find out in the simulation, not after you’ve spent money to change it in the real-world environment.

See Every Angle: Time, Cost, Resources, and Risk in One Model

A major strength of Process360 Live’s simulation is how comprehensive it is. In a single simulation, you can examine time, cost, quality, and resource impacts simultaneously. This means you’re not just getting one narrow metric, you’re getting a full picture of how a change alters your operations.

Time & Throughput

Cycle time drives customer satisfaction and working capital requirements. Process360 Live simulates temporal dynamics with precision that spreadsheets cannot match by modeling time at multiple levels, including individual activity durations, queue times between steps, wait times for resource availability, and system processing delays. These elements combine to determine your true end-to-end cycle time.

Time simulation accounts for variability and interdependencies that kill most process improvement efforts. An approval that usually takes two hours stretches to two days when the approver travels, while a process that runs smoothly at normal volumes bogs down completely during month-end closing. The simulation captures these patterns from your historical data and projects their real impact on performance.

With this realistic foundation in place, you may test various time-reduction strategies systematically by creating parallel processing paths, express lanes for simple transactions, batch size optimization, resource scheduling changes, and so on.

Each scenario reveals precise impacts on average cycle time, variation, and service level achievement, so you know precisely which improvements will work before you implement them.

Cost Simulation, Analysis & ROI

Every step and resource in the model can carry costs, so you can calculate cost per case, labor costs, equipment costs, and more as the simulation runs. This is critical for building a business case.

Process360 Live gives you the numbers to back up (or challenge) the ROI. In fact, the platform can be used to compare results from different simulated scenarios side-by-side, highlighting metrics like total cost, output, and duration for each scenario. This makes it easy to visualize trade-offs.

For example, one scenario might achieve a 20% faster cycle time at a 10% higher cost, while another scenario is slightly slower but much cheaper. Having these comparisons in hand allows you to choose the path that delivers the best ROI or the right balance of cost and speed for your goals.

Resource Utilization

Process360 Live allows you to model resource availability, capacity, work schedules, and time away, so you can test questions like “If we add two analysts, does the bottleneck clear or do they sit idle?” The reports show utilization and queueing patterns per scenario.

In one run, the engine can execute countless cases, effectively running many Monte Carlo trials within a single discrete‑event simulation to surface bottlenecks and utilization patterns that spreadsheets or gut-feel estimates would miss. Furthermore, with real-world schedules, resources, constraints and so on, you can do a far more realistic and powerful analysis than Monte Carlo trials can.

One iGrafx simulation for a manufacturing client exposed that buying an expensive new machine would simply shift the bottleneck elsewhere in the process, providing no real gain. As a result, the company avoided spending over $180,000 on that machine. Instead, they used the model to try other adjustments and discovered changes like rebalancing staffing between shifts that unlocked tens of millions of dollars in potential revenue from improved throughput.

Risk & Variability

Process360 Live’s simulation engine can incorporate real-world process variations to conduct risk analysis on your process changes.

For example, you can input a variability range for inter-arrival times of work (to model an unpredictable influx of support tickets or patients), or include probabilities of rework loops, or random downtime events. The simulation will then show variability in results; e.g., best-case, worst-case, and likely case performance. You might find that a change works well on average but has an unacceptable worst-case outcome (e.g., in 5% of simulations, cycle time blows past your SLA due to a certain combination of delays).

Real-World Impact of Process Simulation

Global consulting firm ZS put Process360 Live at the center of its process excellence work.

They needed a faster way to answer what-if questions, build business cases with real numbers, and move from static maps to living models. With discrete-event simulation, their team builds a partial digital twin of the process, sets arrival rates, step times, and resource calendars, then compares scenarios side by side on time, cost, and capacity. That’s how they validate changes before rollout and choose the best path with confidence.

They shared that traditional tools made this hard. Consultants would map the current state in Visio or Lucid, run time-and-motion studies, and crunch estimates in spreadsheets. It took weeks. When a stakeholder asked, “What if we move this step earlier?”, the team had to recalculate everything. Simulation removed that rework and delay.

Now they model the process once, then iterate quickly. If they add resources, change routing, or parallelize tasks, the model shows the impact on queues, cycle time, and utilization in minutes, not months.

Clinical R&D. ZS modeled the last-patient-last-visit to submission phase. They looked for steps that could run in parallel, where teams used the same inputs but worked sequentially out of habit. In the digital twin, they re-sequenced handoffs, tightened coordination windows, and tested different staffing patterns. The simulated future state cut the timeline by about 48%. Because the model reflected real calendars and variability, stakeholders were comfortable moving forward.

Incentive compensation. Forecast cycles were eating a huge number of manual hours. ZS built a model of the end-to-end work, then simulated automation and off-hours processing. They tested where RPA could take over repetitive tasks and when to trigger jobs overnight to extend the effective workday without adding headcount. The best scenario reduced manual hours by roughly 40% and freed specialists to focus on analysis instead of busywork.

Order to cash (medical devices). Leadership set an ambitious target of increasing throughput by ten times. ZS used simulation to stress-test the current process at that volume. The model surfaced hidden backlogs beyond order entry and showed where systems integration and handoffs would break under load. By rebalancing work, cleaning up handoffs, and removing waste, the team eliminated roughly 55-70% of in-process inefficiencies before touching production.

They also shared lessons that make simulation stick. Perfect data isn’t a prerequisite. Directional inputs from SMEs, backed by spot time studies, are enough to build a useful first model. You set minimum and maximum times on each step, reflect shifts, holidays, and availability, and still get trustworthy results.

Cross-functional buy-in matters as well. Business and IT sit together to ensure the future state is feasible to implement. Most pilots reach a decision-ready business case in six to twelve weeks, then move into change activation with a clear roadmap.

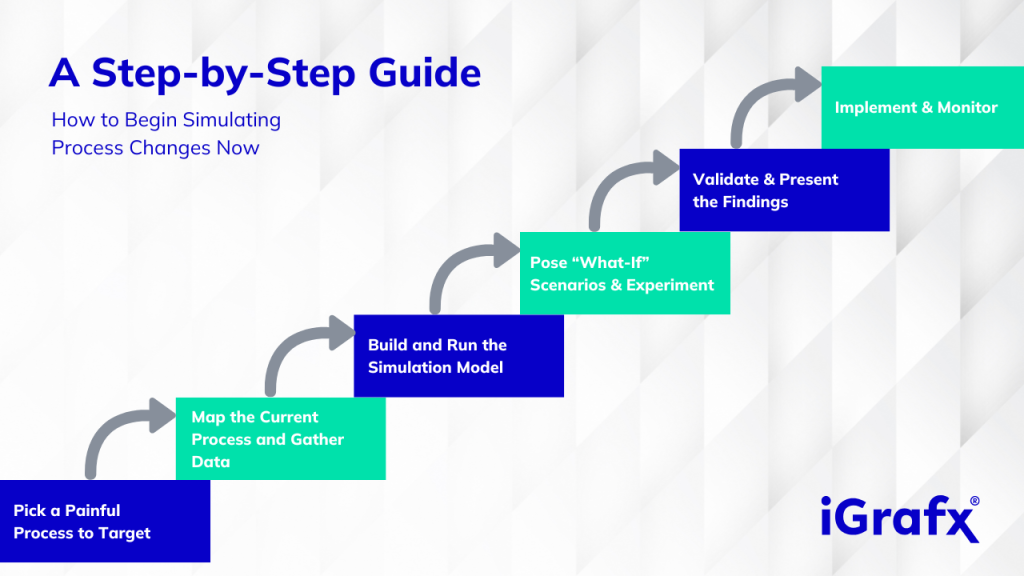

How to Begin Simulating Your Process Changes Now

By now, the benefits of testing business changes virtually should be clear. The next question is, how can your team start leveraging Process360 Live’s simulation right away? Here’s a simple step-by-step action plan to start small, learn the tool, and quickly get value:

1. Pick a Painful Process to Target

Identify one process that is causing significant pain, ideally something with clear inefficiencies or missed targets (e.g., an invoice approval workflow that’s too slow, or a customer service process with high escalations). It helps if you have some data on its current performance (cycle time, volume, error rates), but don’t worry if it’s not perfect.

2. Map the Current Process and Gather Data

Using iGrafx Process360 Live, map out the current state of that process. This is the foundation for your digital twin. If you’ve already documented the process in Visio or a BPMN-compliant tool, you can import it to save time.

If not, work with process owners and SMEs to get key data; or use Process360’s mining capability, to capture the flow from system logs. At the same time, gather basic data for the simulation, things like average task times, arrival rates (how often new work comes in), resources involved and their capacities, and any probabilities (e.g., “20% of orders require rework”). You can start with estimates or rough numbers from subject matter experts. Remember, you can always refine the data later.

3. Build and Run the Simulation Model

Now input that process model and data into Process360 Live’s simulation module. Define your resources, processing times, costs, and any variability or branching logic. The interface will guide you through setting up these parameters with easy dialogs.

Once everything is set, run the simulation for your current state process. The software will crank through many (e.g. thousands to millions) of virtual cases (tokens) to establish a performance baseline. Review the reports and dashboards. Note the baseline metrics like average cycle time, throughput rate, resource utilization, cost per unit, etc. This is your control scenario.

4. Pose “What-If” Scenarios and Experiment

Here’s where the fun begins! Brainstorm a few changes or improvements to test. Start with obvious ideas the team has floated. Create a new scenario in the tool for each idea. This is usually as simple as copying the base model and making the change (e.g., adding a person to a team of 3, or adjusting a routing rule). Run the simulation for each what-if scenario. Process360 Live will automatically compare each scenario’s results to the baseline and to each other.

5. Validate and Present the Findings

Once you discover a promising improvement in the simulation, sanity-check it. Does the scenario make realistic assumptions? (For example, if it assumes hiring staff, double-check that it modeled their cost and availability correctly. If it assumes eliminating a step, confirm that step isn’t required for compliance, etc.) Refine the model if needed and re-run.

When you’re satisfied, compile the results into a brief report or presentation for stakeholders. Include charts or stats from the iGrafx output to give credibility. This data-backed story will help get buy-in to move forward.

6. Implement in the Real World (and Monitor)

With consensus, implement the change in the real process. Because you’ve virtually tested it, you can proceed with confidence that you’ll see the expected improvement. Still, keep an eye on the live metrics to ensure the simulation predictions hold true. In many cases, they will be very close, and if there are minor differences, you can update your model for even better accuracy next time.

Crucially, Process360 Live’s simulation is designed for business users, not just programmers or statisticians. It offers dialog-driven setup and an intuitive interface to build models.

Ready to Take the Guesswork Out of Your Process Changes?

The best way to understand the power of Process360 Live is to see it in action. We invite you to book a demo with iGrafx and discover how easily you can create your own process “what-if” scenarios and digital twins.

Bring your toughest process challenge to the session, and you’ll learn how simulation can tackle it with no risk and high reward. You can also reach out to our team of process experts for a conversation about your goals and how iGrafx can help.

Don’t let another improvement project roll out on a wing and a prayer. Equip yourself with a proven, modern approach to de-risk change, drive efficiency, and hit your performance targets.