Many organizations struggle with recurring issues such as delays in approvals, missed service level agreements (SLAs), or unexpected compliance violations. Despite investments in automation and process redesign technology, these challenges continue to resurface, hindering operational efficiency.

If this situation sounds familiar, you’re not alone. Addressing such problems without a structured approach and the right tools is akin to putting a temporary patch on a flat tire—it offers a short-term fix but fails to address the root cause of the issue.

This is where Root Cause Analysis (RCA) becomes an invaluable tool. RCA helps businesses uncover the true drivers behind inefficiencies, enabling them to understand the underlying causes and develop actionable plans for sustainable improvement.

It’s time to go beyond quick fixes and implement a strategy that will deliver lasting results.

Root Cause Analysis in the Business Process Management (BPM) Era

While traditional RCA relies on subjective interviews and static documentation, potentially missing hidden or systemic issues, modern RCA uses structured, model and data-driven thinking to systematically analyze how business processes behave – and why. By leveraging objective and timestamped data (e.g., from event logs), users can discover process flows, detect inefficiencies, and trace them back to the causes with empirical evidence.

RCA is no longer guesswork: it’s a digital discipline embedded within the BPM lifecycle.

The modern RCA journey begins with detecting problems in your operations. For example, process mining tools can highlight bottlenecks, frequent rework loops, or outlier behaviors through performance analysis and conformance checking. Once a problem area is identified, techniques such as variant analysis or decision rule mining help isolate why the issue occurs – whether due to delays in specific steps, non-compliant paths, or exceptions triggered by certain conditions. Finally, visualizations and dashboards can also contextualize these root causes, making their business impact clear.

The RCA methodology does not necessarily end here and can lead to advanced steps:

- Simulation could allow organizations to test different “what-if” scenarios before committing to process changes, reducing risk, and optimizing decision-making.

- Predictive process monitoring can leverage such knowledge and alert when known causes are expected to occur.

All That Glitters is Not Gold

While RCA is a powerful methodology, its success depends on avoiding a few critical missteps.

One of the most common pitfalls is inadequate problem definition. Without clearly framing the issue – including its scope, impact, and business context – teams can waste time analyzing irrelevant data.

Another trap is focusing on symptoms instead of causes. Process inefficiencies like long cycle times or errors are often surface-level manifestations of deeper structural problems, such as poorly designed workflows or inconsistent data handling. Techniques that focus on causality instead of correlations – e.g., causal inference – will help avoid this pitfall.

Jumping to conclusions without sufficient evidence can lead to misguided interventions. Is the dataset exhaustive enough? Have all important variables been recorded? Effective RCA requires patience, iterative investigation, and a commitment to data-driven validation before implementing changes.

A Marathon Rather Than a Sprint

Root Cause Analysis shouldn’t be a one-time activity, it should be embedded into the BPM lifecycle as a continuous improvement mechanism. Once RCA reveals the drivers of poor performance, those insights should inform process redesign efforts and system configurations. By closing the loop from detection to prevention, RCA not only solves today’s issues but helps build more resilient and agile processes for the future.

By integrating RCA with BPM and process mining, businesses can move beyond reactive problem-solving to proactive optimization.

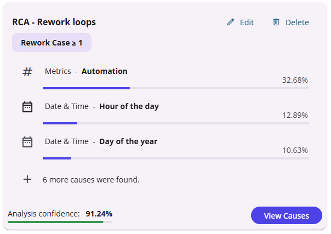

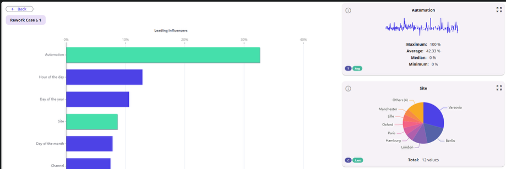

Hands-On RCA in iGrafx Process360 Live

To bring RCA even closer to day-to-day operations, iGrafx is excited to introduce a new capability that empowers users to perform root cause analysis directly within the Process360 Live platform. With this technology, teams can either rely on on-the-shelf analyses or personalized filters to isolate specific process executions – and instantly uncover the most significant contributing factors. Whether you’re troubleshooting individual cases or validating broader trends, this technology provides fast, actionable insights backed by real data.

Ready to see RCA in action? Contact us today.